The biggest advantages of Blow-Fill-Seal (BFS) technology is to prevent external pollution-human interference, environmental pollution, material pollution.

This aseptic packaging process is an automatic process mode which the container is formed, filled, and sealed in one continuous, automated system.

As a mature aseptic filling process which meets GMP in various countries, it is a development trend in the aseptic production field. BFS has long been used in liquid pharmaceutical applications, including small containers, such as ophthalmic and respiratory drug ampoules, as well as larger volume containers, such as saline or dextrose solutions. More recently, BFS technology has been expanding into injectables and into biologics, including vaccines and monoclonal antibodies.

BFS machines make their own containers under aseptic conditions

Low production cost and decrease excessive packaging with shatter-proof plastic containers

BFS machines seal without flame and leave an twist off end for easy injection without contamination risks

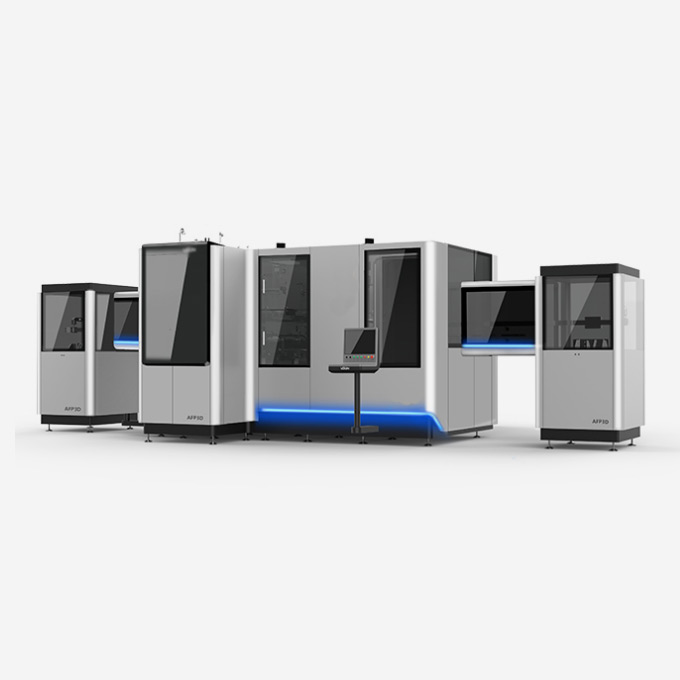

Saves infrastructure investment since BFS equipment occupies a small area

Process is integrated into only one machine with automatic system that will just requires 2 operators

BFS aseptic production environment eliminates sterilization needs when not necessary

BFS creates aseptic filling environment that no additives needed

Starts from raw material that do not needs to be washed

Lower time and capital investment to complete all process on a single BFS machine

ADD: ROOM 1422,NO.5 BUILDING,NO.616,YUNFEI ROAD,NINGBO,CHIAN

TEL: +86-574-87792176

E-MAIL: sales@nb-asic.com